Hybrid DSP Systems

M-COTS VPX AND SOSA FPGA SPECIALISTS

Modified Off-the-Shelf Sensor Processing

Hybrid DSP Systems

M-COTS VPX AND SOSA FPGA SPECIALISTS

Modified Off-the-Shelf Sensor Processing

Full service solution provider in the rugged sensor processing domain.

Full service solution provider in the rugged sensor processing domain.

Hybrid DSP is a European based specialist in rugged FPGA-based processing and data acquisition boards for demanding military, aerospace, and high-end industrial programs. Hybrid DSP, located in the Netherlands, supports tier 1 and 2 contractors in the design, production, integration and long term product and life-cycle management of high-end rugged semi-custom VPX and SOSA solutions.

Our Vision

As an established aerospace and defense electronics company, our vision is to join the industry in shaping the future of embedded systems through innovation, agility, and strategic foresight. We envision a world where our advanced electronic solutions redefine the boundaries of capabilities, ensuring superiority on land, sea and in the air and space. By leveraging breakthrough technologies and fostering a culture of collaboration and excellence, we aim to set new standards, driving the evolution of defense and aerospace solutions.

Our Mission

At Hybrid DSP, our mission is to provide state-of-the-art FPGA-centric electronics solutions that ensure the safety, security, and sovereignty of nations worldwide. We are committed to delivering superior quality products and services that meet the evolving needs of our customers, while upholding the highest standards of integrity, innovation, and reliability. Through continuous development and collaboration with our partners, we strive to become a leading supplier of -open standards based- embedded solutions for European system integrators.

Markets

Hybrid DSP offers -open standards based- board level products and solutions for markets that require high reliability and longevity. Plug-in cards are agnostic to cooling methods and support a wide variety of operating environments, making them highly suitable for a broad range of embedded markets.

What we do

We design and manufacture rugged FPGA and SoC processing and data conversion boards for demanding military, aerospace, high-end industrial programs and communications. We offer licenseable IP for hardware and software products, supporting our customers to deliver uncompromised technology to their clients.

Product design

Design and development of COTS FPGA and SoC boards and technology. Including high-rate data converters and digital interface cards.

Manufacturing

European based manufacturing of COTS and custom boards and assemblies. Including Product Life-Cycle Management services.

Prototyping and M-COTS

Our broad range of reusable hardware libraries, from schematic symbols to completed sections of board layout, accelerates prototyping and low-risk routes to Modified-COTS.

System Integration

For sensor processing systems, the variety of I/O interface types is countless. Our knowhow and experience with FPGA based systems brings the right added value to system integrators who are dealing with a mix of digital and analog I/O.

Design services and consultancy

Our team offers various design services; from developing fully custom VPX boards to creating automated test software applications for integrated systems. And if you need another set of eyes to review your product compliance, we are here to help.

Intellectual Property

We offer licensable IP for all types of technology. From full transfer of production of hardware, to our source available bare-metal VITA 46.11 IPMC core.

Products

Hybrid DSP offers a range of FPGA-based SOSA aligned OpenVPX products. These COTS products are designed with an M-COTS philosophy, allowing for rapid, cost-effective and low-risk modifications. All products come with AXI4 based firmware and software board support packages, making sure that customers don’t waste time getting started with new hardware. Our VITA 46.11 software portfolio includes a bare-metal Tier-3 IPMC implementation and various test- and development tools.

OpenVPX/SOSA Hardware

3U and 6U VPX FPGA processing and I/O boards. All PCB assemblies are cooling agnostic and are offered in air-cooled and conduction-cooled module assemblies. Making them suitable for a variety of markets.

Board Support Packages

Board support packages include RTL designs for all FPGA boards and offer Python- and C-based software libraries and applications. We also offer board support packages for custom and 3rd party FMC’s fitted onto the FPGA carrier boards.

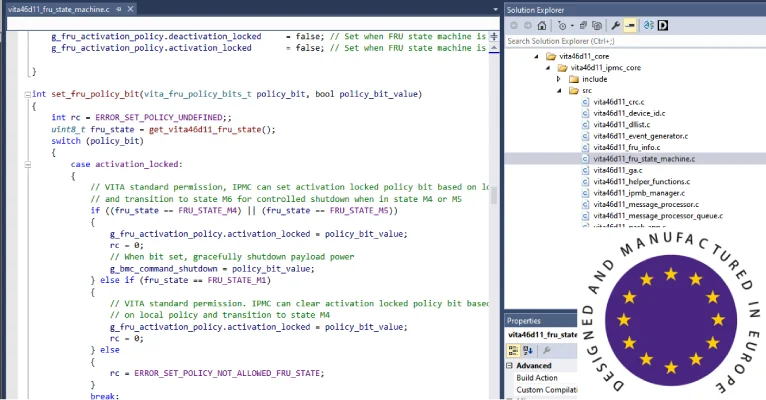

VITA 46.11 IP Cores

The bare-metal C-based VITA 46.11 IPMC core is extremely small and fits in tiny microcontroller devices of various architectures such as PIC32, ARM and RISC-V. The mock chassis manager and compliance verification test software are powerful utilities for test, debugging and integration.

AMD

AMD is pushing the limits of innovation to tackle some of the world’s toughest challenges with their partners

VITA Technologies are a favorite choice in many critical embedded computing architectures. VITA Technologies adhere to the open system architecture definition of real-time, modular critical embedded computing systems. The developers within the VITA community are committed to technology excellence.

Partners

Hybrid DSP cultivates enduring partnerships with top-tier industry collaborators, ensuring the provision of high-quality embedded products and sub-system integration services based on open standards. Our array of best-in-class offerings from esteemed partners complements Hybrid DSP’s extensive portfolio, crafting integrated solutions customized to meet your precise specifications.